Language:

Home / All / Belt Conveyor Series / Pipe Belt Conveyor /

Ce Certificate Heavy Loading Pipe Belt Conveyor for Mining Coal Power Plant

Ce Certificate Heavy Loading Pipe Belt Conveyor for Mining Coal Power Plant

| Categories | Pipe Belt Conveyor |

|---|---|

| Brand | SKE |

| Model | KP |

| color | customized |

| material features | heat resistant, fire resistant |

| applications | chemical industry, mining transport, power plant |

| FOB port | shanghai, china |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | Apr 22,2025 |

Detail Information

Ce Certificate Heavy Loading Pipe Belt Conveyor for Mining Coal Power Plant

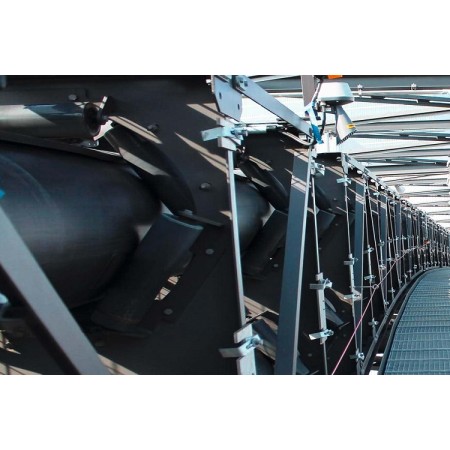

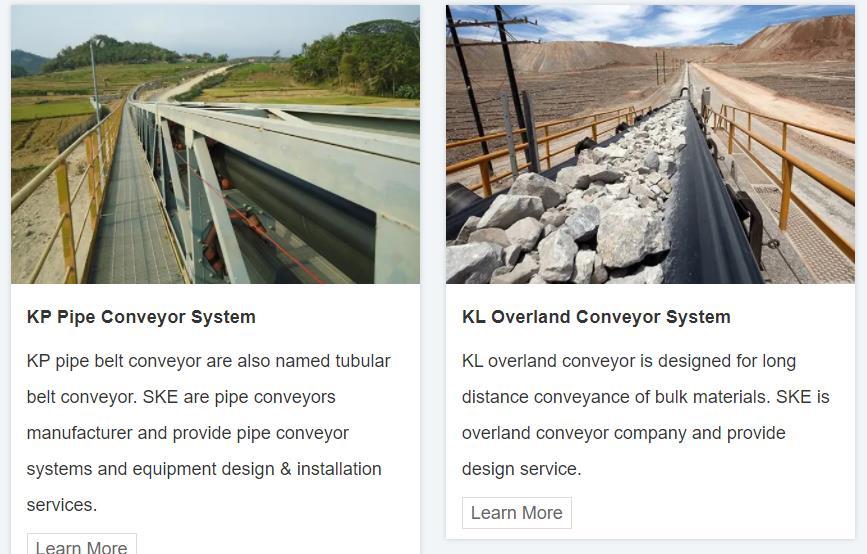

The KP Pipe Conveyor Systems is also known as the pipe belt conveyor system. SKE is a pipe belt conveyor manufacturer in China. We can make bulk materials conveyed in an enclosed and environment friendly conditions come true and protect from leakage, spilling, dust, mixed debris, rain, and snow.

Advantages

1.Conveying bulk material in a closed working condition

2.Long distance conveying and large curvilinear bending

3.It is able to move material in a large angle easily

4.No deviation of round tube pipe belt conveyor

5.Transporting bulk materials in both directions

6.Meet the needs of material conveying in different scenarios

Application

The KP Pipe Belt Conveyor is a special type of conveyors developed on the basis of the through belt conveyor. We usually use six idlers to form a regular polygon idler group to force the conveyor belt to form a circle.

Industries: It is able to be widely used in thermal power plant, building materials, chemical industry, metallurgy, mining, coal, ports, grain and other industries.

Materials: Coal, coke, coal ash, metal ores (gold, silver, copper, iron, lead, zinc, etc.), ore powder, sinter ore, non-metallic ores (marble, basalt, limestone, granite, potash, trona, salt, phosphate, etc), alternative fuel, slag, gravel aggregate, fertilizer, grain (soybean, corn, wheat) ,etc.

Methods: The pipe belt conveyor can be divided into unidirectional and bidirectional conveyors, of which the unidirectional material transportation can be subdivided into two types of one-way pipe forming and two-way pipe forming.

Tech Datasheet

| Specifications of KP pipe conveyor system | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe diameter(dp/mm) | Belt Width(b/mm) | Belt pipe conveyor systems belt speed v/(m/s) | |||||||||

| 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | 4.5 | 5.0 | ||

| 100 | 430 | 17.0 | 21.2 | 26.5 | 33.9 | — | — | — | — | — | — |

| 150 | 600 | 38.0 | 47.5 | 59.4 | 76.0 | 95.0 | 118.8 | — | — | — | — |

| 200 | 750 | 66.5 | 83.1 | 103.9 | 133.0 | 166.2 | 207.8 | — | — | — | — |

| 250 | 1000 | 117.9 | 147.4 | 184.3 | 235.8 | 294.8 | 368.5 | 464.3 | — | — | — |

| 300 | 1100 | 141.1 | 176.4 | 211.7 | 282.2 | 352.8 | 441.0 | 555.7 | 705.6 | — | — |

| 350 | 1300 | — | 237.6 | 297.0 | 380.2 | 497.2 | 594.0 | 748.4 | 950.4 | 1069.2 | 1188.0 |

| 400 | 1600 | — | 388.8 | 486.0 | 622.1 | 777.6 | 972.0 | 1224.7 | 1555.2 | 1749.6 | 1944.0 |

| 500 | 1900 | — | 558.1 | 697.6 | 893.0 | 1116.2 | 1395.3 | 1758.0 | 2232.4 | 2511.5 | 2790.5 |

| 600 | 2250 | — | 777.6 | 972.0 | 1244.2 | 1555.2 | 1944.0 | 2449.4 | 3110.4 | 3499.2 | 3888.0 |

| 700 | 2550 | — | 1008.0 | 1260.0 | 1612.8 | 2016.0 | 2520.0 | 3175.2 | 4032.0 | 4536.2 | 5040.2 |

| 850 | 3100 | — | 1454.4 | 1818.0 | 2327.0 | 2908.8 | 3636.0 | 4580.0 | 5817.6 | 6544.8 | 7272.0 |

Related

Please send your message to us

- Tel

- *Title

- *Content

NAVIGATION

KEEP IN TOUCH

Please send your message to us

- Tel

- *Title

- *Content

CONTACT US

subscription