Language:

Home / All / Belt Conveyor Series / Large Inclined Belt Conveyor /

Large angle belt conveyor for mixed batch plant application no sprinkling

Large angle belt conveyor for mixed batch plant application no sprinkling

| Categories | Large Inclined Belt Conveyor |

|---|---|

| Brand | SKE |

| Model | B650/B800/B1000 |

| Color | Customized |

| Inclined angle | 10-60 ° |

| Capacity | 100-1000 tph |

| Application | Mixed batch plant |

| FOB port | Shanghai |

| Terms of Payment | L/C, Western Union, T/T |

| Update Time | Apr 28,2025 |

Detail Information

Description

Large angle belt conveyor for mixed batch plant application no sprinkling:The biggest feature of the Large inclined belt conveyor (known as corrugated edge belt conveyor) structure is to replace the ordinary conveyor belt with a corrugated edge belt. Its working principle and structural composition are the same as the general belt conveyor.

This structure of the conveyor is designed for conveying materials with a large inclination. The use of the conveyor belt, through the secondary vulcanization with a certain height of the partition and corrugated edge ribs, on the transmission line to form an effective load-bearing material volume, the purpose of conveying materials has been completed. This product can convey bulk density of 0.5 ~ 2.5t/m3 in the ambient temperature range of -25 ℃ ~ 40 ℃;

The maximum conveying angle is 90 °, and the maximum conveying material block is 550mm;

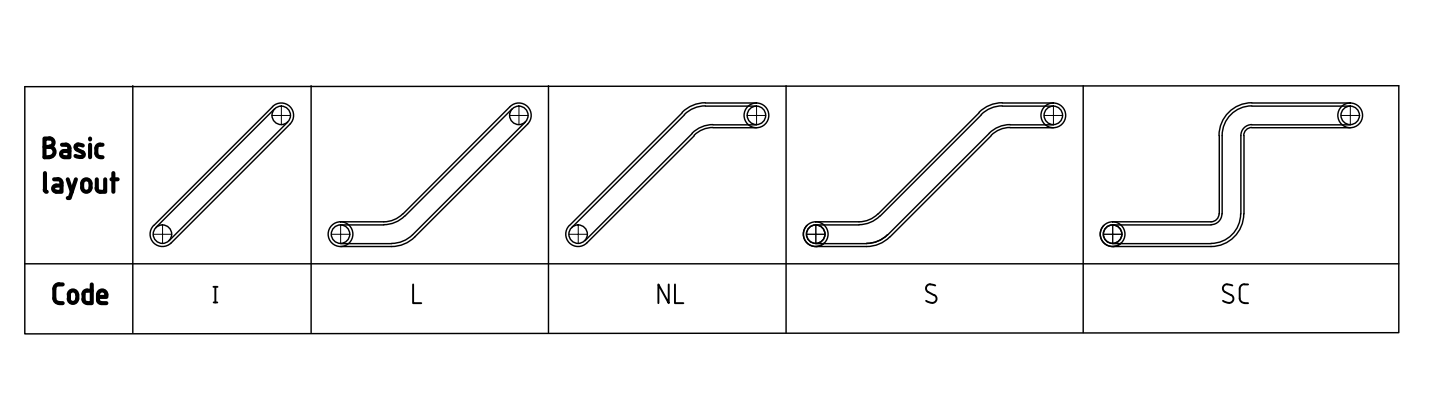

Different types of large angle belt conveyor

Feature

1. The conveyor belt with corrugated edge ribs and transverse partitions is used. Its allowable conveying inclination angle is large up to 90 °. It is an ideal equipment for large inclination angle conveying and vertical lifting

2. It can save floor space, equipment investment and civil construction costs, and has higher comprehensive economic benefits

3. Simple structure, stable operation and low noise.

4. Reliable operation. There is no stuck chain, floating chain, broken chain phenomenon that often occurs in the buried scraper conveyor, and slippage and drop of the bucket elevator that often occur. Its reliability is almost equal to general belt conveyors.

5. Because there is no internal friction or external friction resistance of the material during operation, the energy consumption is low.

6. It can also set a horizontal conveying section of any length on the head and tail to facilitate connection with other equipment.

7. Large conveying capacity.

Application

Specification

Effective belt width (mm) | Edge Height (mm) | Speed (m/s) | Inclined Angle (°) | Capacity (m3/h) | Power (kw) |

80 | 84 | ||||

100 | 112 | ||||

120 | 98 | ||||

100 | 156 | ||||

120 | 140 | ||||

160 | 186 | ||||

120 | 186 | ||||

160 | 318 | ||||

200 | 360 | ||||

160 | 428 | ||||

200 | 483 | ||||

240 | 683 | ||||

160 | 535 | ||||

200 |

765 |

||||

240 | 1077 | ||||

200 |

920 |

||||

240 |

1298 |

||||

300 |

1657 |

Please send your message to us

- Tel

- *Title

- *Content

NAVIGATION

KEEP IN TOUCH

Please send your message to us

- Tel

- *Title

- *Content

CONTACT US

subscription