Language:

Home / All / Belt Conveyor Series / Fixed Belt Conveyor /

DTII Type Fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials

DTII Type Fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials

| Categories | Fixed Belt Conveyor |

|---|---|

| Brand | SKE |

| Model | B500/B650/B800/B1000/B1200/B1400/B1600 |

| Color | Customized |

| Application | aggregate/ mix batch plant/ grain/coal etc |

| FOB port | Shanghai,China |

| Terms of Payment | L/C, T/T |

| Update Time | Apr 26,2025 |

Detail Information

Description

DTII Type Fixed Belt Conveyor are widely used in metallurgy, mines, coal, power station, building materials. DT Ⅱ is a combination of TD75 and DX series (i.e. general type and high-strength type), which can be divided into three types according to bearing capacity: light, medium and heavy. The complete conveying sustem is suposed to be designed by single or multi units. It can convey various bulk materials with a bulk density of 500-2500kg / m3. The applicable ambient temperature is - 25 ℃ ~ + 40 ℃. For the belt conveyor working in special environment, the conveyor belt is required to be heat resistance, cold resistance, water resistance, corrosion protection, explosion-proof, flame-retardant, etc., meanwhile the corresponding protective measures shall be taken separately. This series of belt conveyor is designed according to the parts, which has high universality.

SKE can carry out the free detailed design of the conveyor according to the flow diagram provided by the customer, and provide the calculation sheet, general drawing, parts list, foundation size, foundation load and other data to the customer and the Design Institute in a short period, or carry out the design after the data is inspected on site.

Application

It can be widely used in metallurgy, mines, coal, ports, power stations, building materials, chemical industry, light industry, machinery, petroleum and other industries.

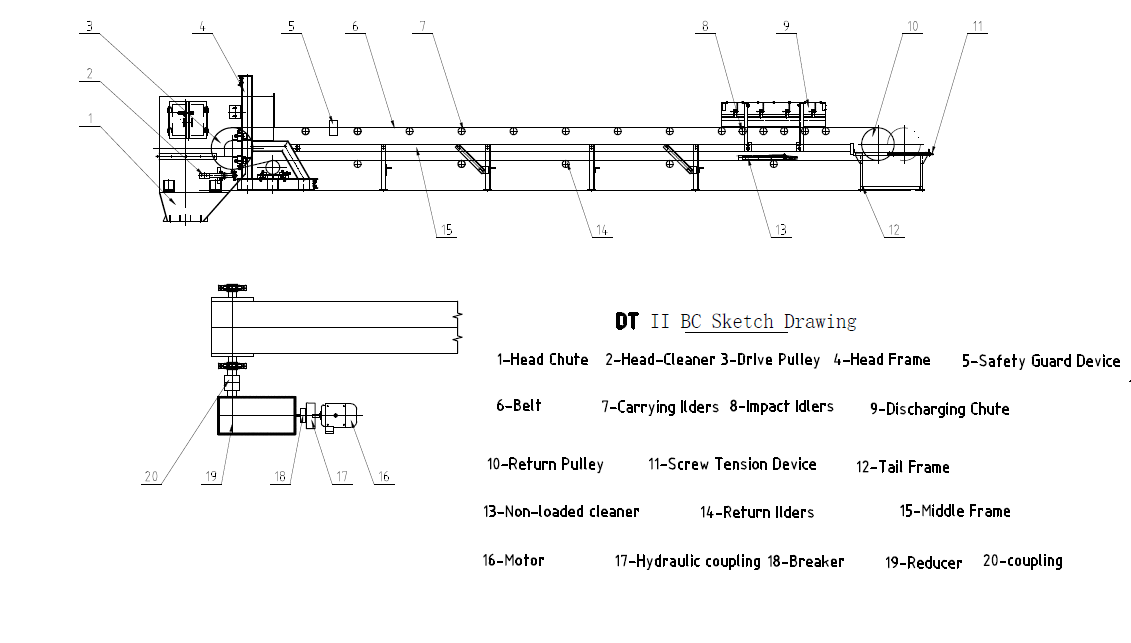

DT II Main components

Features

1)A wide range of conveying materials

2)Wide range of conveying capacity

3)Strong adaptability of conveying line

4)Flexible loading and unloading

5)Strong reliability

6)Low maintenance costs

7)Strong reliability

8)High safety

Technical Specifications

Width | Capacity IV (m3h) |

|||||||||||

Speed V (m/s) |

||||||||||||

0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | (4.5) | 5.0 | (5.6) | 6.5 | |

500 | 69 | 87 | 108 | 139 | 174 | 217 | -- | -- | -- |

-- |

-- |

-- |

650 | 127 | 159 | 198 | 254 | 318 | 397 | -- | -- | -- | -- | -- | -- |

800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | -- | -- | -- | -- | -- |

1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | -- | -- | -- | -- |

1200 | -- | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2674 | 2971 | -- | -- |

1400 | -- | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 3718 | 4130 | -- | -- |

1600 | -- | -- | -- | -- | 2186 | 2733 | 3444 | 4373 | 4920 | 5466 | 6122 | -- |

1800 | -- | -- | -- | -- | 2795 | 3494 | 4403 | 5591 | 6291 | 6989 | 7829 | 9083 |

2000 | -- | -- | -- | -- | 3470 | 4338 | 5466 | 6941 | 7808 | 8676 | 9717 | 11277 |

2200 | -- | -- | -- | -- | -- | -- | 6843 | 8600 | 9776 |

10863 |

12166 |

14120 |

Note:

1. The delivery capacity ( IV ) is calculated according to the attribute transportation when the dynamic stacking angle is 20 ° and the idler groove angle is 35 °

2. The belt speed (4.5) and (5.6) m / s in the table are non-standard values, which are generally not recommended.

Please send your message to us

- Tel

- *Title

- *Content

NAVIGATION

KEEP IN TOUCH

Please send your message to us

- Tel

- *Title

- *Content

CONTACT US

subscription